You can make informed decisions based on accurate asset information

Informed asset management decisions stem from accurate information about your assets. The first step is establishing an accurate asset register with the appropriate information about each asset that you need to enable good asset management practice and make appropriate decisions. The asset register is the foundation for good asset management. A well-defined asset register, with a logical hierarchy and asset classification structure will enable most asset engineering functions.

Accurate asset information in a well-defined asset register enables you to

- Reduce your cost of maintenance by establishing effective maintenance strategies

- Improve the performance of your assets through reliability engineering

- Make informed decisions based on accurate reporting on asset and cost performance

- Make informed decisions to drive out waste and reduce costs based on asset data analytics

- Develop effective asset management plans to achieve your business goals by understanding the risk profile of your asset base

Five-stage process for developing an accurate asset register

- Develop an asset classification standard

- Develop the asset information master data standard

- Undertake physical asset validation

- Develop the asset hierarchy

- Asset information system data upload

Develop and accurate asset register

In order to develop an accurate asset register, there is a need to validate what you have in your current information systems against what is actually physically present. For greenfield operations, the validation is generally not required if construction and commissioning information like line diagrams, asset registers and as-built drawings are available. Asset validation can either be done by Covaris, utilising our expertise and our web-based and mobile technology or it can be done by your people that are trained to use our processes and technology. Covaris has the capability and capacity to perform the asset validation process end-to-end or skill up your people to perform this function.

So how does it work and what do you get?

Develop an asset classification standard

We will work with your organisation to develop an appropriate asset type/classification standard that will standardise the approach to capturing asset data information for asset types/classes. Where applicable, Covaris uses industry standards. For example (but not limited to) :

- International Infrastructure Maintenance Manual (IIMM) ;

- Uniformat 2; and

- Kraftwerk-Kennzeichen-System (KKS).

Development of an asset type/classification standard that is applied to all of your assets will enable:

- Development of effective maintenance strategies;

- reliability engineering functions;

- asset management planning; and

- asset class performance, cost analysis and reporting.

Develop the asset information master data standard

The asset information master data standard is developed in order to standardise what information will be collected for each asset. The information collected has to be useful to the organisation in enabling asset management functions. The master data asset attribute information will also be aligned in the asset information system (depending on capability). The basic recommended asset data to be collected is:

- Asset Identification Data – Asset ID, Name, Description, etc. A descriptive name familiar to the asset stakeholders. The description requires sufficient detail to enable identification of the applicable asset classification.

- Asset Location: The location allows the spatial position of the asset being evaluated to be specified.

- Valuation Data (where available): used to identify value and actual lives of the assets.

- Asset Condition: used for decision making and analysis of effective life and condition-based remaining life

- Asset Type / Asset Classification

Undertake physical asset validation

The information captured in the field is aligned with the master data standard. As part of the asset validation we perform a visual condition assessment as it is highly cost effective. The technology we use allows us to perform this function quickly and without adding any real overhead to the project. Covaris will use your condition assessment procedure, or if one does not exist, we can develop a procedure appropriate for you.

We use modern technology that allows us to deliver this service with:

- High speed and efficiency;

- high process and data quality; and

- low cost to you.

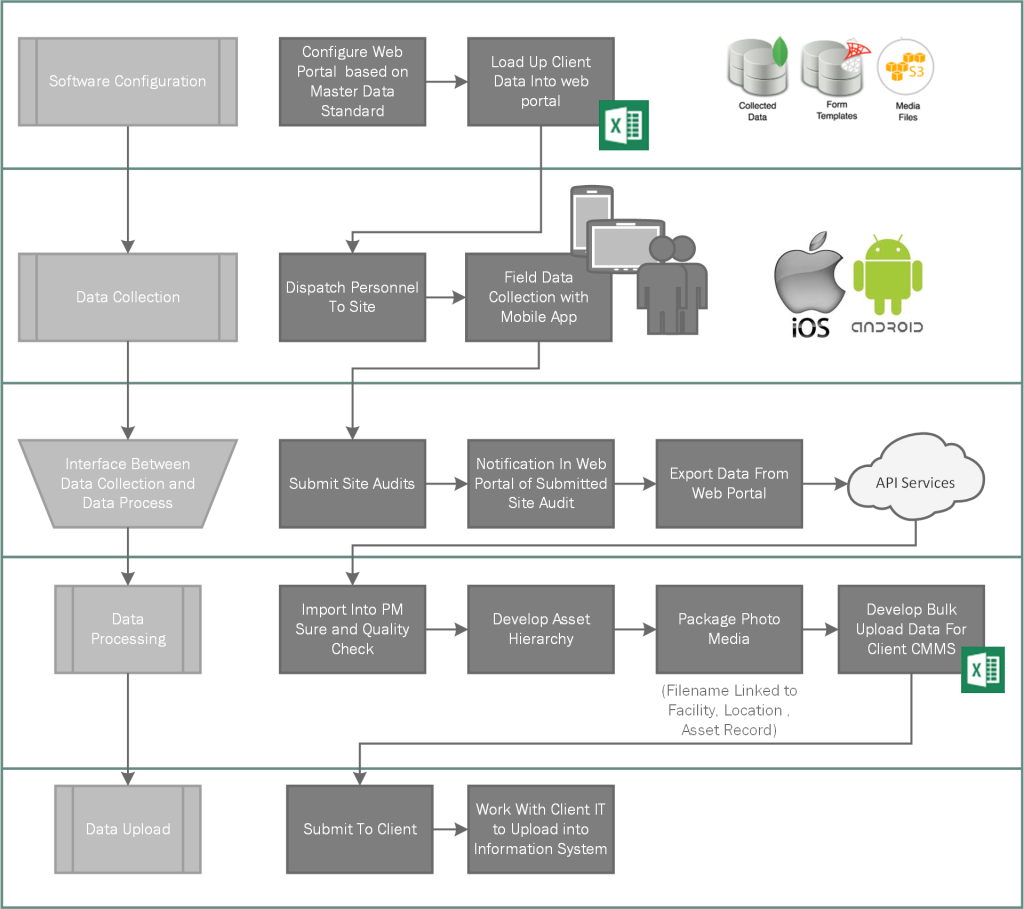

Our asset validation process is shown below:

Develop the asset hierarchy

We use our proprietary software PM Sure to quality check the field validation data against the master data standard and to create the logical asset hierarchy. The outcomes that we seek from an asset hierarchy is to ensure that when established:

- It is easy to locate equipment in the complex asset base

- Work results such as costs for equipment can be rolled up to parent levels for reporting purposes

- Work can be allocated to the maintainable item so that the life cycle costs of assets can be determined

- PMs will be set at the right level in the hierarchy to facilitate good schedule control which translates to efficient use of the labour resource

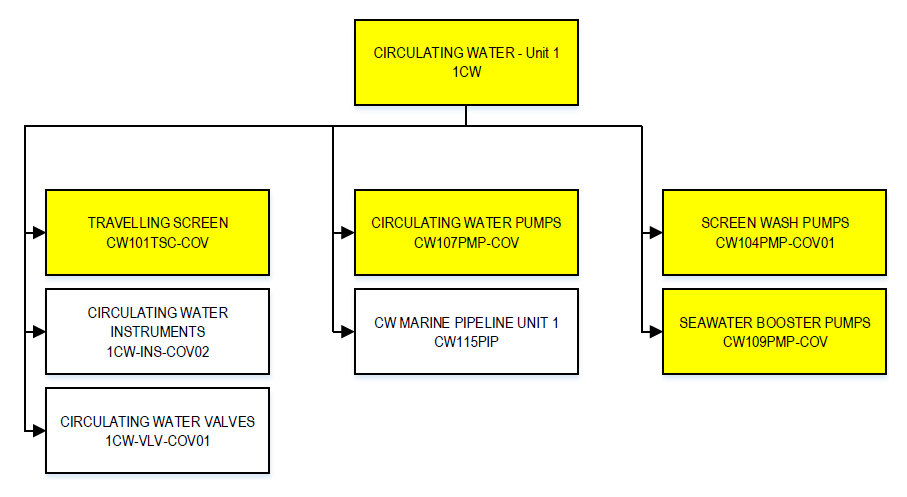

Our approach to development of an asset hierarchy is to map the equipment and identify the relationships between the assets to be maintained. The level of detail that is necessary for adequate maintenance systems design is quite extensive. This is often the major problem to an improvement team, where in most cases there is a not enough documentation and local knowledge regarding some machines, despite their criticality to the process. We use a cluster mapping technique to overcome these issues. The cluster maps are an important technique for the team to understand the scope of a machine/process and its maintenance requirements. An example of a cluster map can be seen below.

CMMS, EAM, ERP asset information system data upload

We will export the asset data, and any photo media in any format required for upload by your IT department. In past projects, we work with the IT department and their bulk upload tools or spreadsheets and export the data to fit with their existing processes. Covaris has experience with most contemporary EAM, CMMS, ERP systems (e.g. MAXIMO, SAP, MAINPAC, MEX) and can also assist in the upload if required.